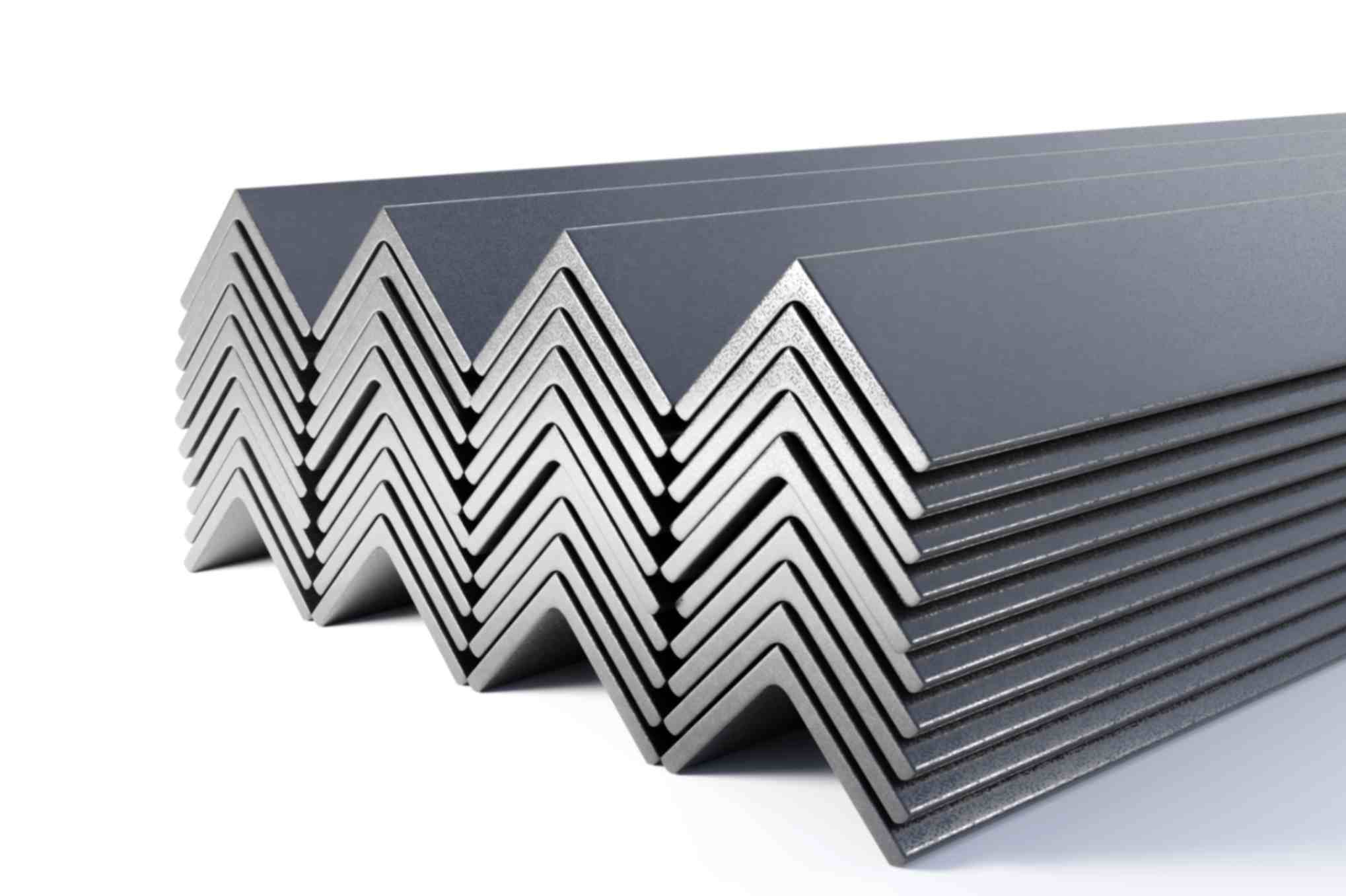

Angels are structural steel components with an "L"-shaped cross-section, which most commonly finds use in construction, fabrication, and engineering applications. These are used materially in mild steel, stainless steel, and aluminum, among other materials. Excellent strength, durability, and resistance to corrosion are notable excellences. They are either of equal or unequal leg sizes, rendering extensive support and reinforcement in framing, bridges, towers, and industrial buildings. They are also widely used in shelving, brackets, and appliances. They are hot-rolled or cold-formed and more commonly available with smooth or galvanized finishes to aid corrosion protection. The lack of detail in their use has immense adaptive value, is easy to work with, and is inexpensive, making it quite fundamental for load-bearing use in stabilizing structures and reliability in various sectors of industries including infrastructure, transportation, and manufacturing.

Benefits

1.High strength and durability- Angles are excellent structural supports and load bearers; they are perfectly suited for the construction and industrial uses.

2.Versatile- They are applied in frames, brackets, towers, bridges, and machinery in industries such as construction, transport, and manufacturing.

3.Rust and Environment Resistance- Galvanized and stainless versions offer angles rust and environmental corrosion resistance.

4.Economical- They are a highly economical structural solution because they are readily available and easy to fabricate.

5.Light but strong- Angles deliver strength with minimal weight.